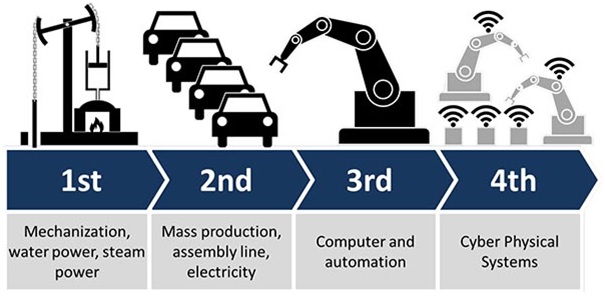

The uncertain environment brought by the spread of coronavirus has created a perfect impetus for innovation. The creation of cyber-physical systems (CPS) means that we now have the capability to store data in a sophisticated manner and regulate automated processes without being physically present.

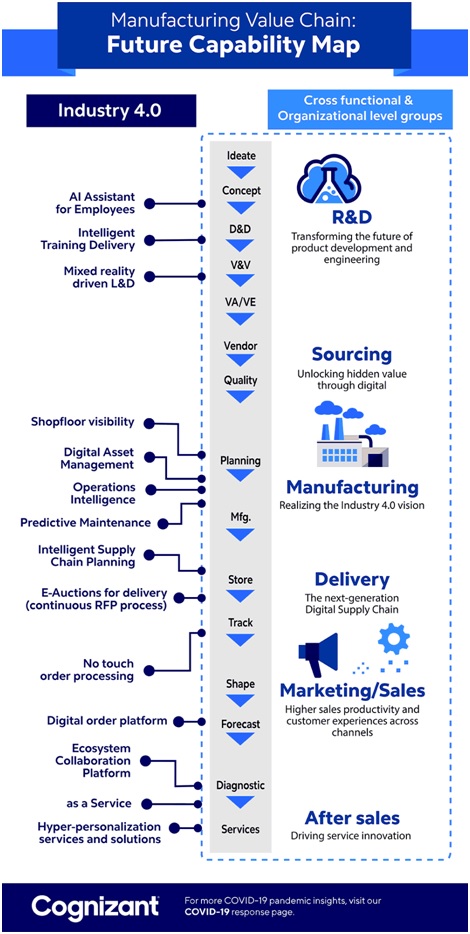

Companies around the globe are finding ways to reduce dependency on human labour: which is exactly the goal achieved by dark factories, smart factories and the IIoT. Dark factories or lights out manufacturing are the epitome of current innovation, where completely automated processes take place without any human physically present on the factory premises. In smart factories, however, humans and machinery operate side by side. While the labour force required is significantly reduced, there still needs to be human oversight for production processes.

The above existence of the above systems is made possible due to several elements of sophisticated technology, that include:

- Artificial Intelligence

- Blockchain Manufacturing

- Industrial Internet of Things

- Condition Monitoring

- Robotics

- Cyber Security

- 3-D Printing

- Quantum Computing

- Nanotechnology

What’s important to note is that companies were on this path already – COVID just accelerated it. Pre crisis, the changes were more calculated and cautious, with long gestation periods. Now, driven by necessity, manufacturing units are tranforming within the span of months—each aiming to be as resilient as possible. This is also an opportunity for businesses to improve their functionality and services.

Over the year, COVID’19 has transformed manufacturing processes in a multitude of ways. Even when humans are stuck at home, machines are not, and can continue producing output uninterrupted. Less people on the factory floor translates into lower chances of infection, and it is easier to maintain social distancing norms. Industry 4.0 has also played its part in directly tackling the virus. For instance, in China, thermal drones are being used to scan for citizens with fever. Smartphone apps, that have been introduced by several countries globally, help mass data as people track their symptoms. These innovations are also being utilised to make the mass-production of PPE gear more efficient.

Manufacturers now also have access to larger blockchain networks, creating a larger network for inputs and finished goods. Creation of more complex IIoT networks has enabled several manufacturers to detect and prevent assembly line failures, and using video monitoring, Virtual and Augmented Reality tools can go a long way in enabling workers to carry out functions remotely. Robots can now serve the needs of organisations of all sizes, like the ones used by Amazon warehouses: to enable better use of floor space, and quickly and safely move goods around.